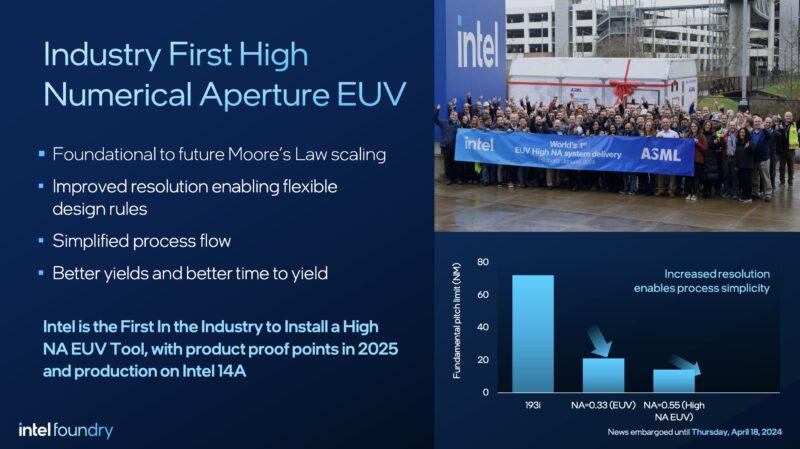

Intel Foundry announced today that it has the second High Numerical Aperture Extreme Ultra Violet (High NA EUV) machine in Oregon. The ASML Twinscan EXE:5000 is a foundational tool for the company’s 14A process node in 2025 and is second only to ASML’s first machine. This is one of the first machines that cost on the order of $400M that will lead to better chips in the near future.

Intel High NA EUV Milestone Readies for 14A Production

Today Intel Foundry is announcing that it has installed the first tool in Oregon. Installing a tool is one thing, but then there are many steps to go from installed machine to actually making chips.

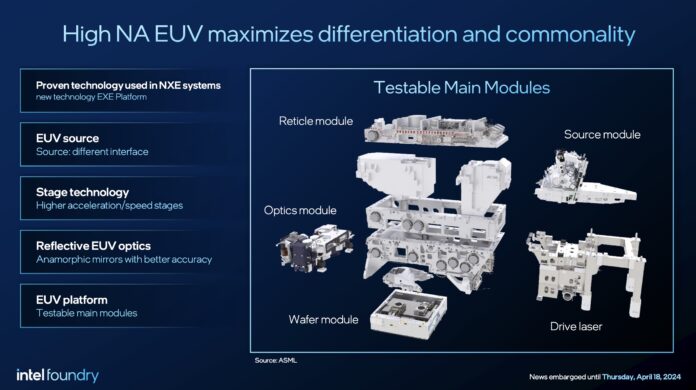

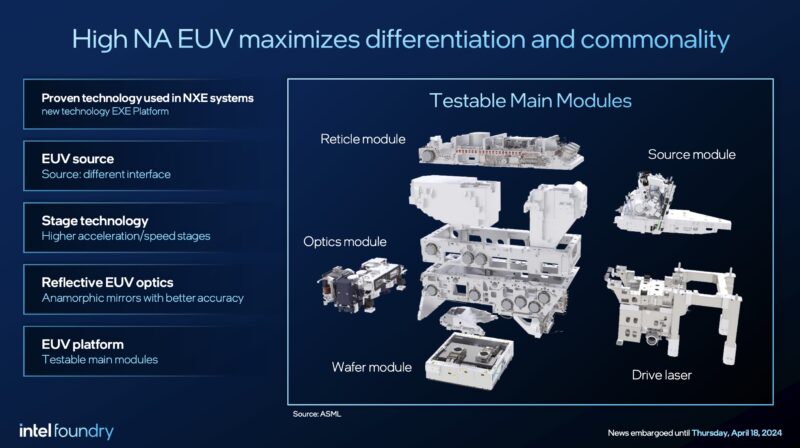

The ASML machine has a number of components that can be tested and upgraded separately. Intel says that it has been working with ASML on the tool for many years so it is confident in the 14A production schedule.

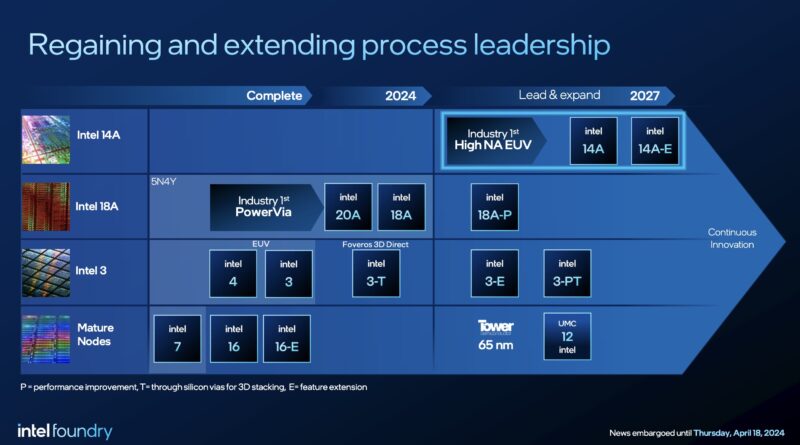

High NA EUV is targeted for 2025 and Intel 14A. Intel said they expect High NA EUV to be around the industry for several process nodes.

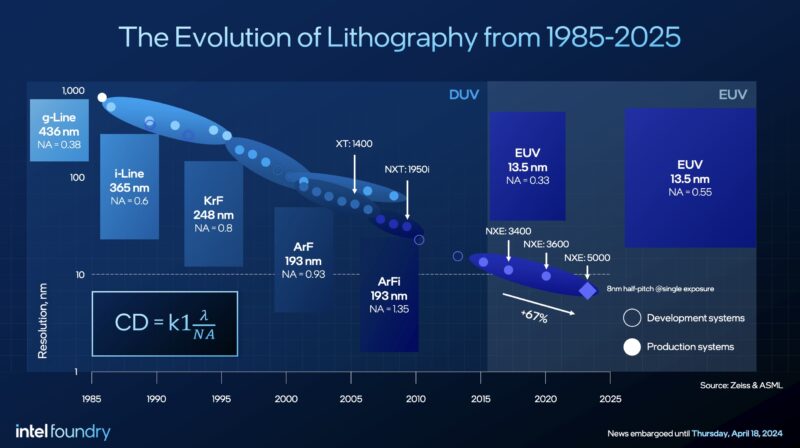

Here is a view of lithography from 1985 to 2025 that Intel Foundry presented from Zeiss and ASML.

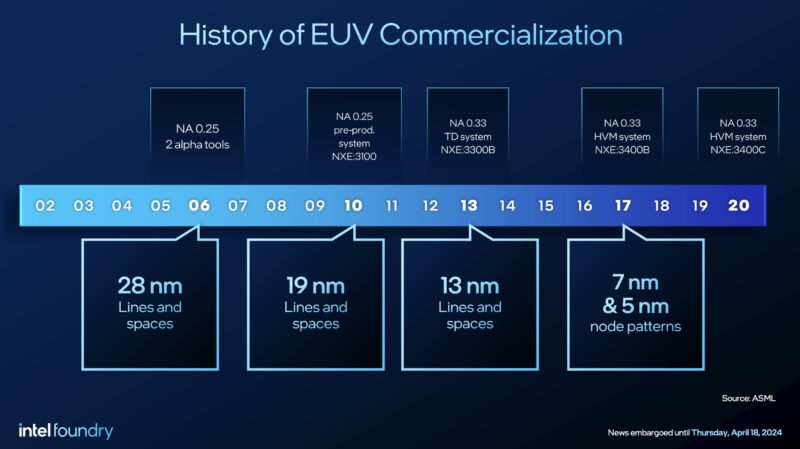

There is also a deep-dive of EUV commercialization. Intel went with DUV instead of EUV for 10nm and that is famous in the industry as a reason that Intel 10nm was massively delayed. It is also a major reason Arm processors, AMD CPUs, and so forth were able to leapfrog Intel Xeon by using TSMC. Before the disastrous 10nm transition, alternatives could get a few percent better due to architecture, but Intel would own the process leadership and still win in actual chips. One of the reasons Intel Foundry is talking fabs is to assure Intel Products that it can deliver on time, but also as a message to external customers. Missing a critical technology inflection can leave you with a disadvantaged product. That is newer messaging from Intel as it seeks to regain leadership later in 2024.

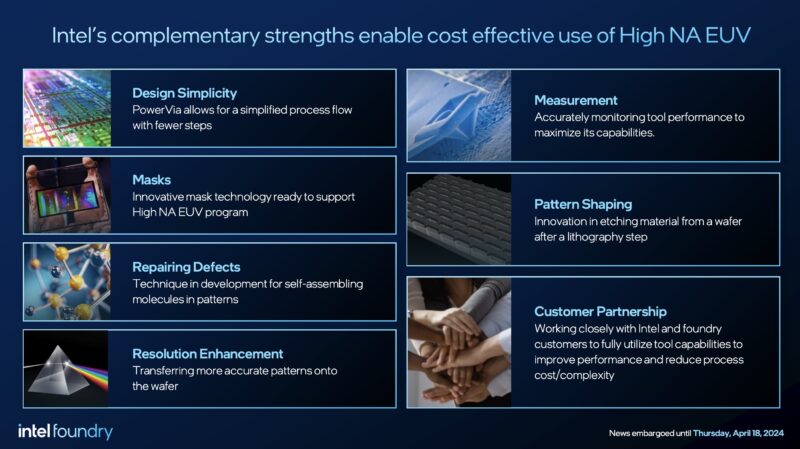

Intel Foundry also has a number of supporting technologies that it has been progressing along with the High NA EUV development.

Something important is that today’s chips are very complex and High NA EUV machines by ASML are designed to have higher wafer throughput, but also are more expensive. As a result, High NA EUV is going to be used on many of the critical layers of a chip, not for the entire chip manufacturing process.

Final Words

Next up for Intel Foundry is first light with basic exposure. Intel expects the new tool to be up and running by later in 2024. It will go from technology development for 14A in Oregon and then begin production hopefully in 2025.

TSMC has enjoyed several years of technology leadership. It is important that Intel Foundry competes because in the end that means better cheaper chips for the industry.