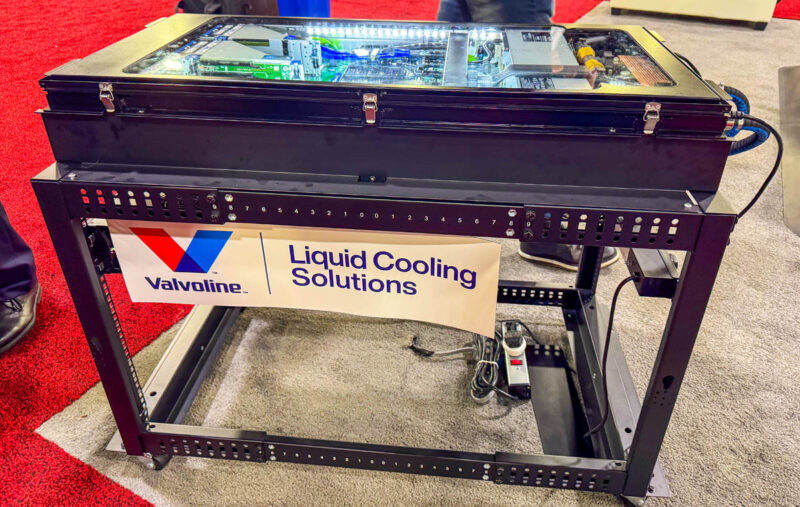

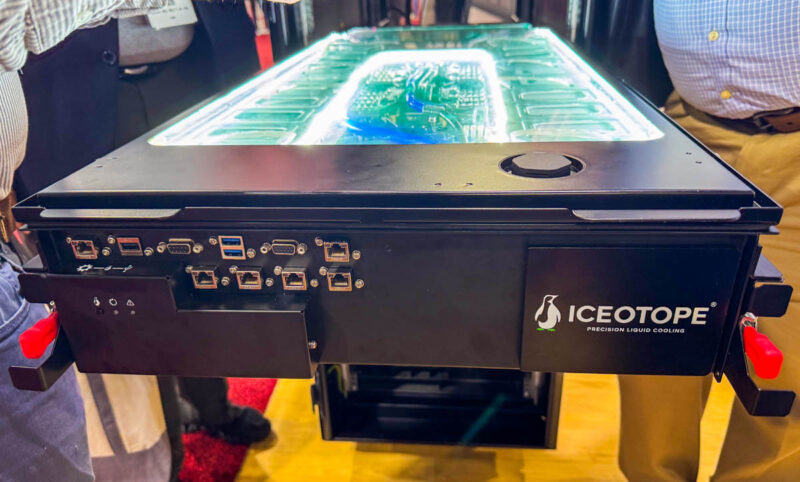

Iceotope has a really neat dielectric liquid cooling setup, and it was again showcased at SC24. We saw a demo of lceotope’s KUL EXTREME with the Valvoline Immersion Heat Transfer Fluid DE1 at the show. The booth was dominated by an Aston Martin Formula 1 car, but we still managed to find the liquid cooling.

Iceotope Immersion Cooling and Valvoline Fluid at SC24

Just behind the booth car, we found a Startech rack with a server sitting atop it.

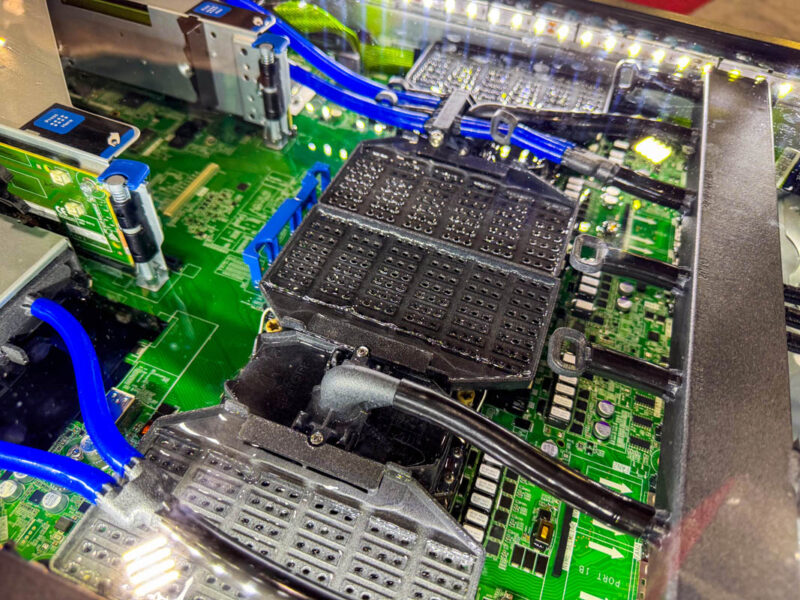

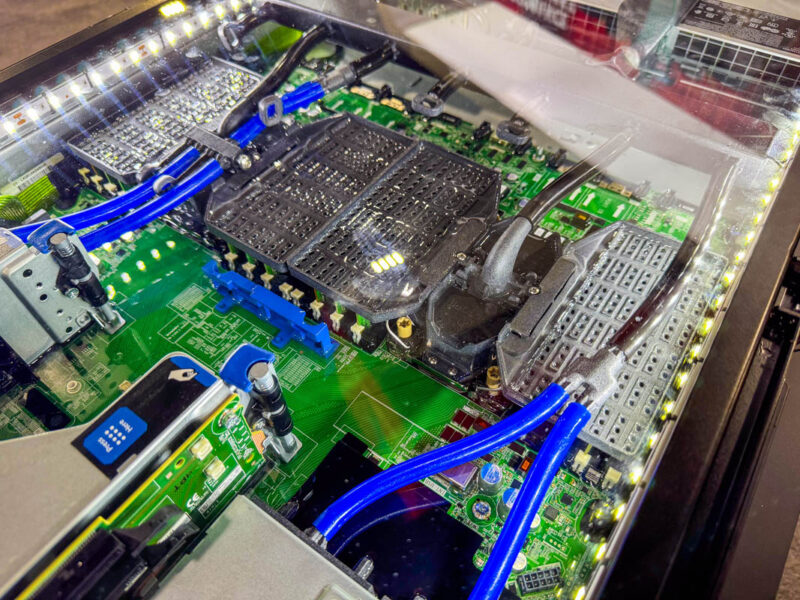

We actually found two of these Iceotope systems on the show floor, but here is a photo of a larger GPU cooled system.

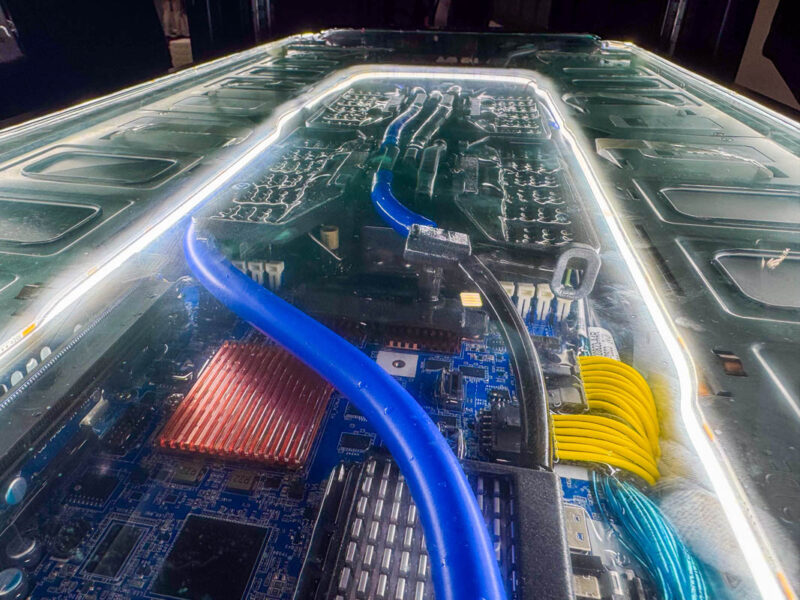

Iceotope has a very different approach to immersion cooling. Instead of mounting the systems oriented vertically in large tanks full of fluid, Iceotope has horizontal systems that use a smaller amount of fluid.

The fluid is then directed to and poured over the hot components.

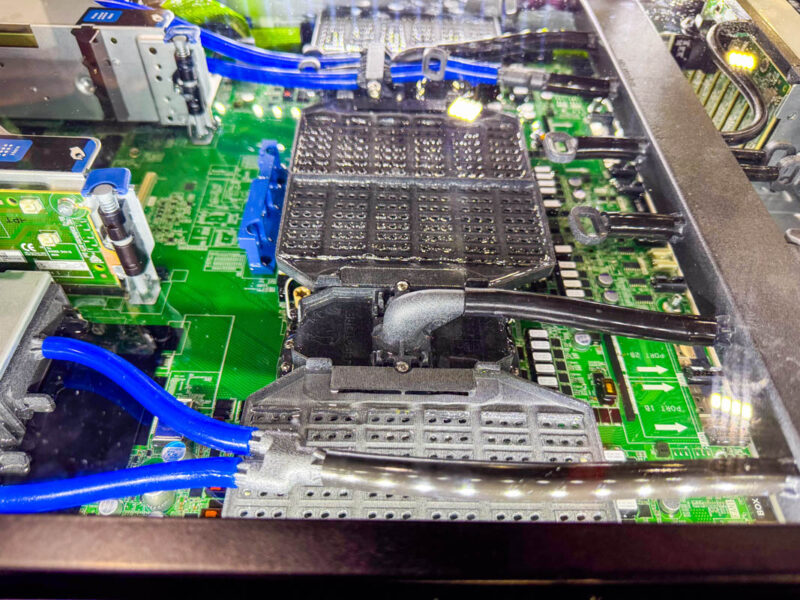

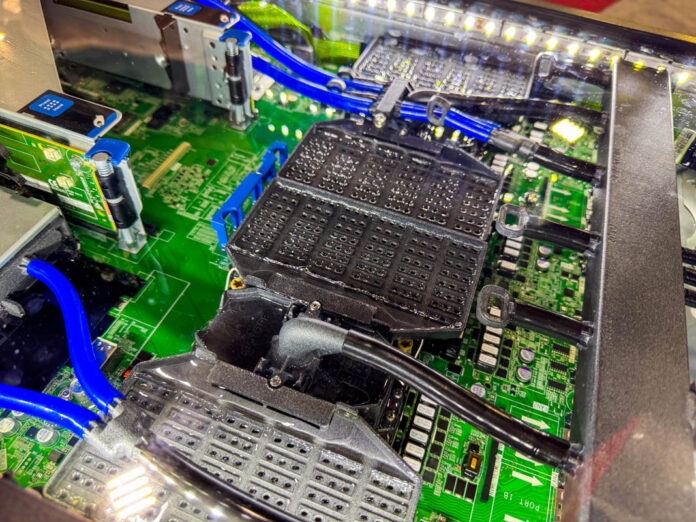

Part of what Iceotope has been working on is the most effective way to deliver the fluid onto the electronic components. You can see the holes that are helping to direct this flow.

The key here is that instead of just sitting in a tank of fluid, the fluid is directed over the hottest components. That means only a small layer of fluid is atop the components.

The fluid then flows to the collection area at the bottom of the chassis where a heat exchager removes the heat to aisle or facility loops and the now cooler fluid can be pumped back onto CPUs, GPUs, memory and more.

As a result, we have things like a little fill port for each server.

This is always a neat system to see.

Final Words

Folks may have seen an older generation Iceotope cool sink in the STH YouTube studio starting in Austin next to the smiley face sign for many years. This is one that is a really neat idea, and a way to lower the total amount of fluid required to cool hot components. It also integrates more easily into a lot of data centers since one gets immersion cooling but in vertical racks instead of horizontal tanks. Using less fluid lowers the cost as does using lower-cost coolsinks. Overall, a cool demo that we have been meaning to show on STH for some time.

Do they say what the cooling fluid is made of? Seems like not too long ago y’all had an article about direct-immersion cooling fluids containing PFAs which are harmful to the environment as well as IT maintenance personnel health. Would be nice if Valvoline could weigh in on this as it’s kind of important.

@Stephen Beets, as best I can tell from Valvoline’s site: https://www.valvolineglobal.com/en/valvoline-heat-transfer-fluids-pg/

and running the product name through their SDS lookup(which doesn’t seem to generate direct links; but is linked to on the product page); it’s an unspecified concentration of propylene glycol; presumably along with various anticorrosion things; rather than a fluorocarbon based chemistry.

When the SDS is claiming that the concentration of the primary ingredient is a trade secret at precisions greater than a 10% band it’s not necessarily a comprehensive rundown of exactly how the sausage is made; but it’s definitely not one of the historical mostly fluorine chemistry ones whose biological inertness has not panned out as intended.

I assume that it’s not necessarily easy to tell from the tech demo; but is there any sign of whether going horizontal makes preventing spills and creep more difficult?

Looks like they’ve brought out a bunch of low-ish speed interfaces on pigtails; which should be fine for GigE BMC connections, VGA, USB, and the like; but which seems much less helpful for the sort of high speed interfaces that you are going to see on systems that are worth the hassle of immersion cooling.

Do they have similar options for multiple 100GbE connection scenarios? Is the comparatively innocuous and low cost thermal material intended to make drain-to-service an acceptable options for a lot of things where ports that don’t leak would be too fiddly?

@fuzzyfuzzyfungus

Thanks. So… probably the same stuff as in the coolant in your car. That’s good. Toxic in “too much” amounts, but not environmentally dangerous in the same way as PFA-based formulas. Just the answer I was looking for. Again, thank you. I rate your reply five stars. :-)

@Stephen Beets

WHO recommends no more than 2.5kg a day for an average weight adult male when ingested as a food additive. Wouldn’t call PG “toxic”…