Yesterday, we published our piece on Why Servers Are Using So Much Power. In the accompanying video, we showed off the Vertiv Powerbar solutions, including the High Powerbar. These provide a way to deliver flexible power to racks overhead. If you have never seen these in action, they are a bit different than the older methods of running power under a raised floor and easier to swap.

A Look at the Vertiv Powerbar and High Powerbar for Overhead Power

We showed some video of this, including Patrick installing a tap-off box at around 10:10 in the video yesterday:

Here is the lower-capacity Vertiv Powerbar.

The tap-off boxes are designed so they physically engage the bar’s electrical pathways only if they are installed properly with the handle on top moving levers on the other side of the box.

One of the big advantages is that you can configure the boxes for different breakers, plugs, and so forth by using a different box. For example, here is a dual L5-20R tap-off box. A common installation setup would be to have one of these Powerbars for each of a rack’s A+B power feeds.

We had a photo of how the tap-off box latches onto the rail. As the handle is engaged, the physical latch grabs the Powerbar and the electrical fingers go into the designated Powerbar channels. We tried installing these improperly, and the handle would not engage. That is a safety feature.

There was another version, the High Powerbar. This is a version that can handle much more power, ranging from 1000A-5000A.

This has a slightly different locking mechanism for the boxes, but the idea is similar. They engage when they are aligned properly to do so. These are called bus plugs and are rated at up to 600A each.

These are designed not just for a handful of racks. Instead, this is a solution to deliver power through a data hall, or a hospital floor, or another high-power area. Since there are diverse buildings that these will go into, on of the features is not just the straight rail, but also the way the rails connect to one another, and are connected to other gear and the building.

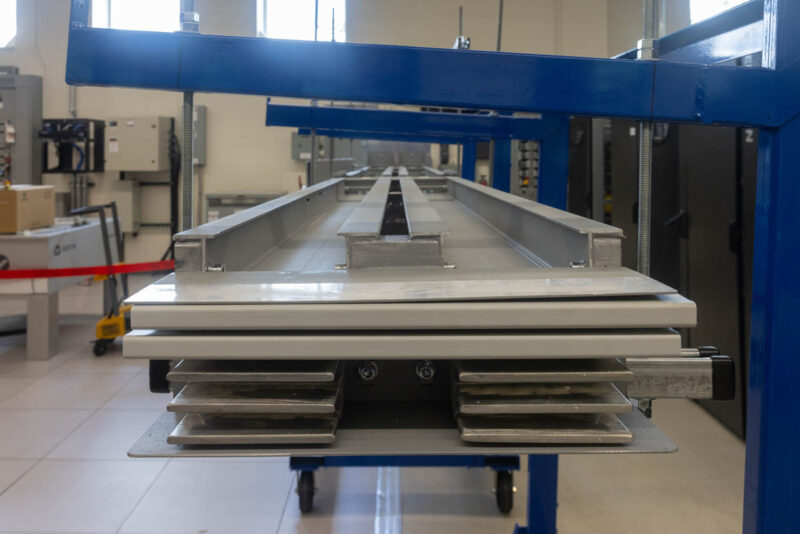

Here is a great profile view from inside the training center. There are flanges designed to connect to switch gear, transformers, and so forth.

Here is the other end of the training High Powerbar.

Perhaps more interesting for folks might be to see a shot down the busbar.

Connecting multiple segments looks something like this coupler. There are other angled couplers and flanges that we did not get to see.

Still, it gives some idea of how these things are put together. One can imagine these running overhead. From these busbars one can place boxes where needed, and the types of boxes needed. That can be useful if you, for example, do a project to change the floor layout of a data center.

Final Words

Vertiv has a number of different versions and attachments. Still, at STH, we use some colocation facilities with these overhead power distribution solutions and some with under-raised floor solutions. We have had some of these racks upgraded to higher power, and doing it with overhead Powerbars is much easier.

We thought our readers might like to see this kind of gear, since many have never seen anything like it.

Very interesting, but it seems a bit unwieldy – is this because the DC has to run on 120V and that’s why the higher currents are needed? The DCs I’ve been in have all been 415V 3-phase (which is 240V per phase, so normal 240V single phase equipment is used), and appear to have around 50A per phase coming into each rack, but I guess that ~36 kW per rack isn’t enough given the other article linked talks about 100-120 kW per rack.

I didn’t realise DCs were rearranged often enough to need something like this though. I always assumed some underfloor cables to each rack would be just as flexible and much more cost effective, but I suppose if you’re now looking at 150 amp cables (at 415/240V, to get > 100 kW) then a few runs in parallel will quickly add up in material cost alone, and make something like the Vertiv more attractive.

A 150A capable cable would need to be in the region of 100mm square, and if you’ve ever worked with these they are incredibly heavy. Not something you want under the floor blocking the cold air flow (given that at those capacities they’ll be putting out their own heat too).

Solutions like this one are useful as you can drop additional boxes in for more capacity without needing to run more cables under the floor, of spending the money upfront to cable every possible rack location before they’ve even been sold.

At my last job, our brand new HQ used the high power rails to move mains power between floors. We had 2MW of service to the building.

What’s the black thing with the blue label on the right of the photo of the High Powerbar? I ask because the same thing is seen in this video from inside a Google data center (you’ll need to pause to catch it) at https://youtu.be/FsxthdQ_sL4?t=69

It seems like it might be an inspection access door but I am not sure why you’d need to inspect the middle of a bus duct.

This is the E+I IMPB and high current PowerBar product from before Vertiv fairly recently acquired them.

If you look at recent datacenter construction announcements where companies are putting hundreds of megawatts / gigawatts on a campus, that would be utterly infeasible running cords under a floor to the racks.

“What’s the black thing with the blue label on the right of the photo of the High Powerbar? I ask because the same thing is seen in this video from inside a Google data center (you’ll need to pause to catch it) at https://youtu.be/FsxthdQ_sL4?t=69

It seems like it might be an inspection access door but I am not sure why you’d need to inspect the middle of a bus duct.”

On the lower current bus bar product shown, you can put a tapcan wherever you want. You’re actually looking at the conductors through a narrow finger-safe channel.

On the higher current bar the bus is enclosed and you only have specific spots you can add a tap box. This helps reduce energy release if there was a fault at the tap connection / inside the bus. That black cover with blue label covers one of the windows you can remove to install a tap. If you look at the “Vertiv High Powerbar Tap Off Box” picture above you can see where they’ve taken the black cover off of its hinge to install the tap box. Those are short demo sections of bus, hence why they only have one tap spot on them.

You can get an idea from that video, campuses like that will have many many miles of this type of bus.