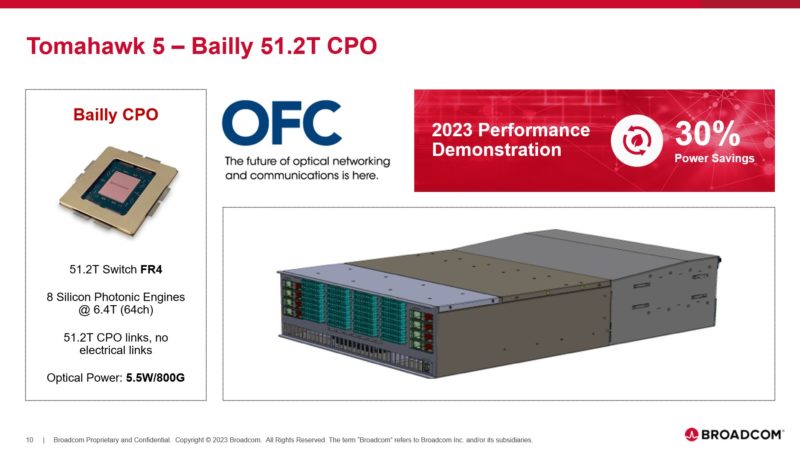

This is awesome. This week Broadcom is announcing that its Bailly co-packaged optics switch is not just an engineering prototype. Instead, the 51.2T Tomahawk 5 Bailly switch is now sampling to OEMs/ ODMs.

Broadcom Now Sampling 51.2T Co-Packaged Optics Switch

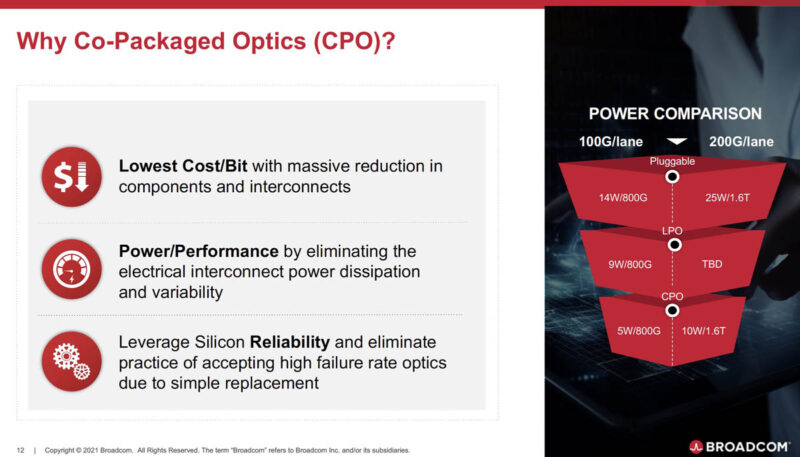

Co-packaged optics have been a hot topic in the industry for some time. We have seen a number of iterations on how to do it, but it seems like there is now a model to implement the solution, and the power consumption savings are real. We published our first hands-on with the Intel Co-Packaged Optics and Silicon Photonics Switch four years ago. Since then, Broadcom has taken the lead in this space, speeds have increased, and the practical implementation challenges have been iterated on.

Above is the video from that hands-on. It was published about 2.5 months after starting the YouTube journey and we should hit 500K subscribers tomorrow if trends hold another 24 hours. Still, that is perhaps one of the best resources folks in the industry remind us of often at STH.

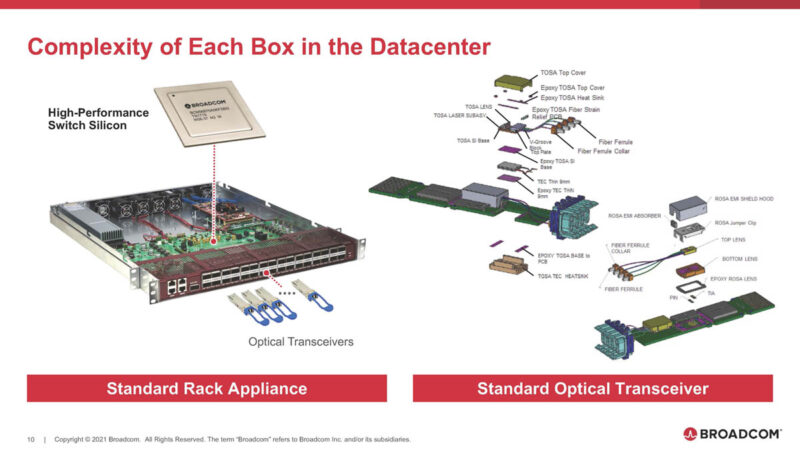

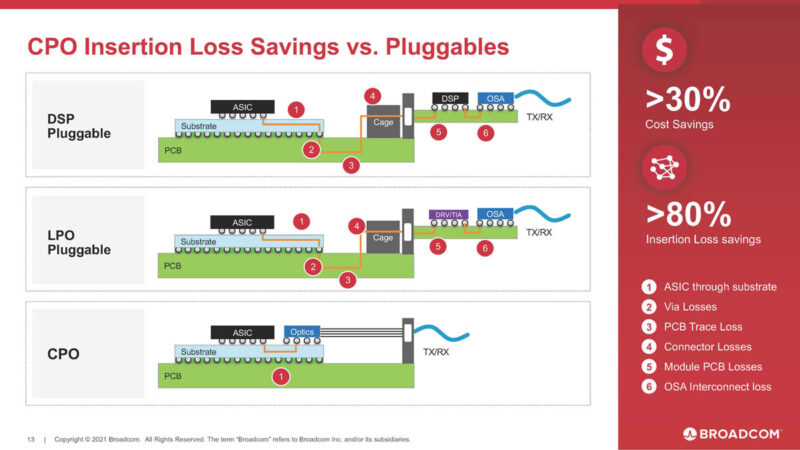

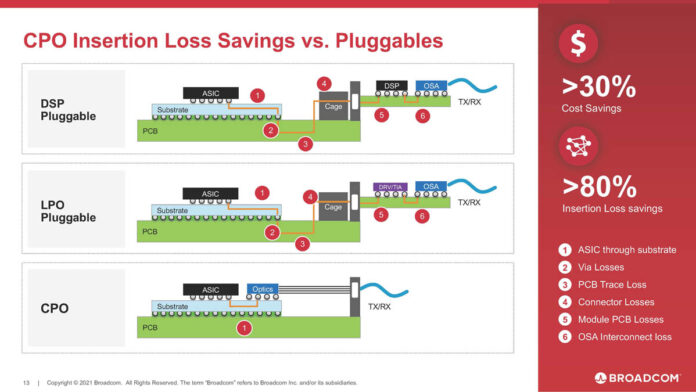

Taking a quick look, Broadcom has a breakdown of the components used in a typical pluggable optic module and all of the pieces that go into supporting that model.

By co-packaging the optics, high-speed and power-hungry PHYs do not need to drive the signal from the switch silicon to the faceplate pluggable module cages. One area that the industry has used is cabled connections between the switch and the pluggable modules. Almost everyone we talk to, however, believes co-packaged optics are the future into the 1.6T era and beyond.

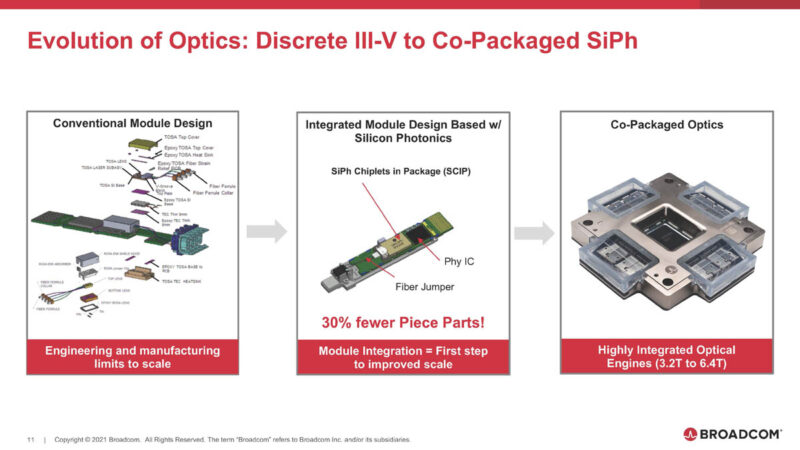

The way that the optics have evolved is that they have been simplified and then packaged alongside the switch silicon.

A year ago, we covered Broadcom Tomahawk 5 based 51.2T Bailly Co-Packaged Optics Switch Shown. Since then, it has gone from concept to reality.

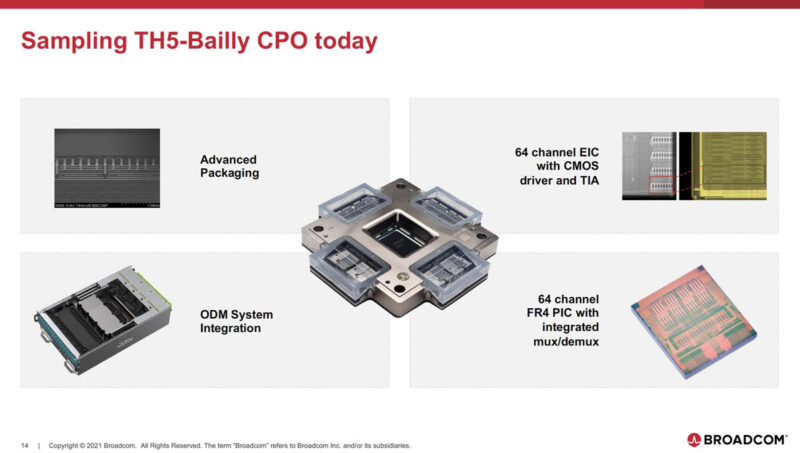

The new Tomahawk 5 Bailly switch with co-packaged optics uses optical modules (shown here with protective dust covers over them) co-packaged alongside the Tomahawk 5 switch silicon. From there, pigtails are used inside the chassis to help get light to the front panel of switches.

Interestingly, Broadcom is not showing the internal cable options that some vendors are using, but the company had a slide on sources of loss using traditional pluggable modules. Another big factor here is that the path between the ASIC and optics over the substrate is significantly more efficient in driving high-speed electrical signals over, compared to PCB. Once the signal goes optical, the distance between the switch chip and the front panel is negligible compared to the typical 2km FR4 optical reach.

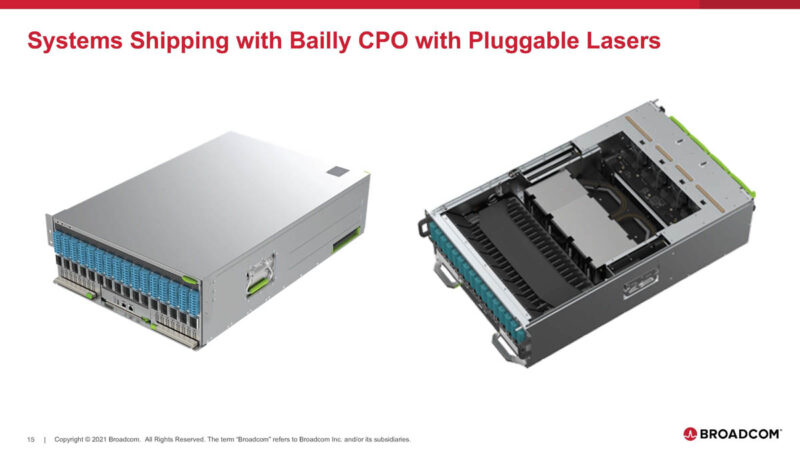

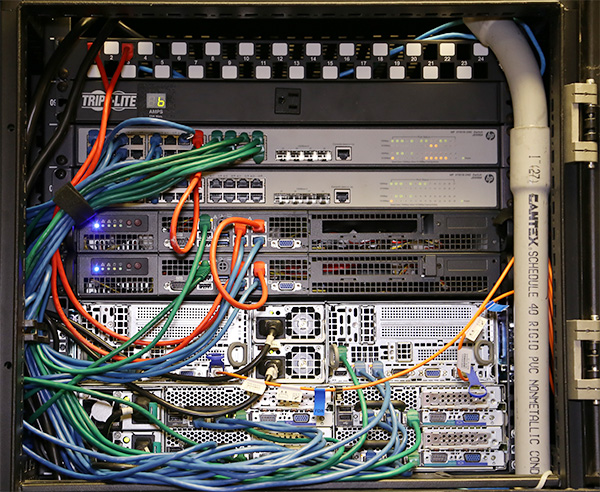

Something else that is not here is that the CPO’s light source is a pluggable module. Light sources are devices with higher failure rates, so they are plugged into the outside of a switch. Below is a Facebook Minipack-style switch with LC connectors on the front. Below that is a pluggable slot for the pluggable light source.

It is easy to imagine how a liquid-cooled switch with MPO/MTP connectivity could make for extremely high-density 1U switches.

Final Words

Hopefully, we will get to do more co-packaged optics pieces in 2024-2025, as the technology can save a lot of power that is being wasted today to move data a few cm in a switch. Co-packaged optics will be more important as we move to the 800G and then to the 1.6T era. Still, today, Broadcom can now claim it is sampling its co-packaged optics solution to customers.

I had no idea that these high-speed optics had small thermoelectric cooling elements in them! Of course, thinking about it for a moment, it seems obvious that that keeping the lasers at a stable temperature, not just cooling them would be a major thermal consideration.