This week, Cisco showed its vision for co-packaged optics. Instead of simply showing that co-packaged optics are possible, it also showed why we need them and how it plans to tackle some of the deployment challenges.

Cisco Touts Co-Packaged Optics Future with Demo

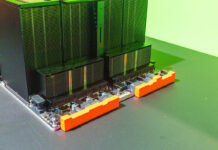

This week, Cisco showed off its co-packaged optics demo switch. For those unfamiliar with the concept, the idea is to move the Silicon Photonics modules onto the switch package instead of using pluggable models.

Although Intel has stopped Barefoot development, we were able to take a look at an early generation co-packaged optics switch Hands-on with the Intel Co-Packaged Optics and Silicon Photonics Switch. (Ed: Maybe time for a thumbnail change on that, one of our very early videos.)

We also recently covered Broadcom Tomahawk 5 based 51.2T Bailly Co-Packaged Optics Switch Shown and the earlier version.

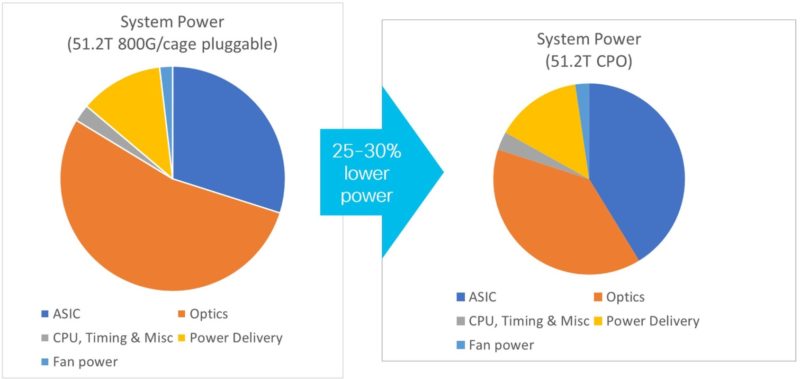

This is clearly the way the industry will evolve. One of the biggest reasons is power consumption. Here is Cisco’s chat showing just how much of a switch power can be reduced through co-packaged optics. For some sense, we have a 64-port 400GbE switch we are testing that can use over 2kW, and an enormous part of that (about half) comes from powering and cooling the optical modules. That is similar to the Cisco co-packaged optics demo above, but with traditional pluggable optics.

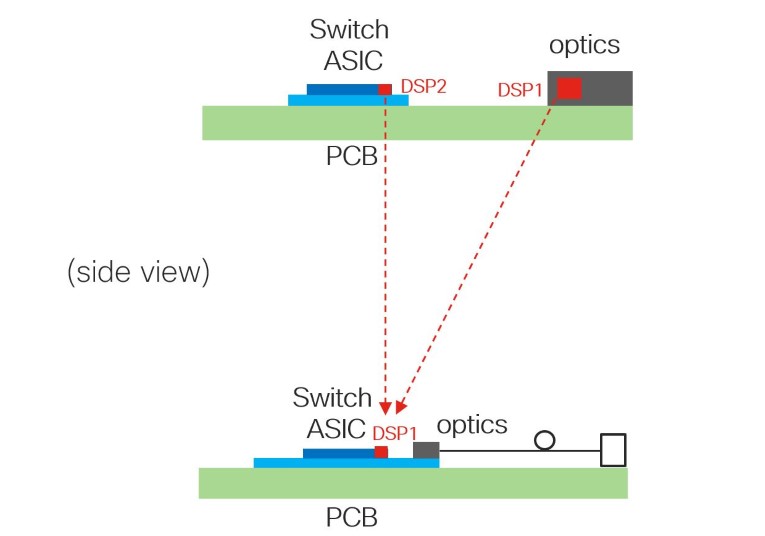

Cisco’s solution of co-packaging the optics means that one of the DSPs required to drive the signal across the PCB can be removed. That has enormous power savings, especially as speeds increase.

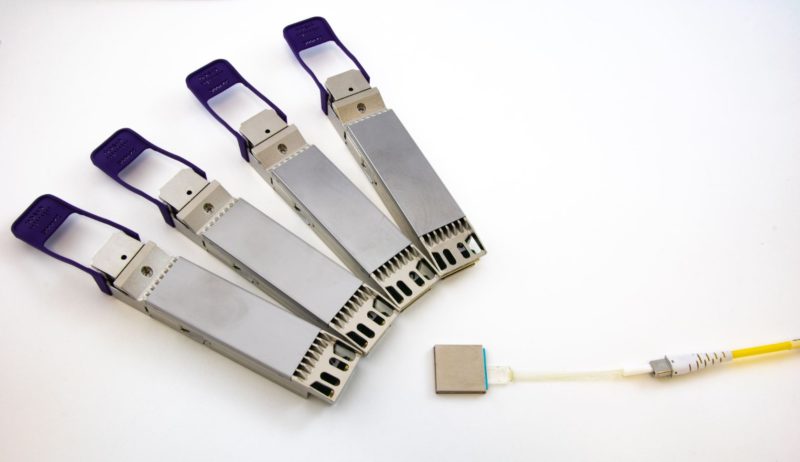

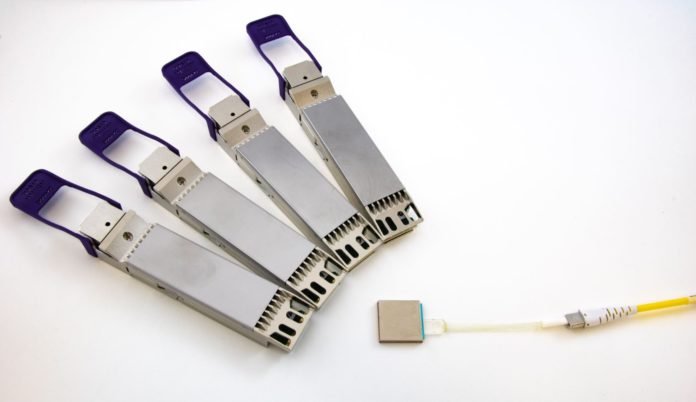

Putting a co-packaged optics module in the space of a chip footprint instead of a pluggable module creates another challenge: space. Here are four 800Gbps OSFP800 pluggable optical modules and a Cisco CPO module side-by-side. There is a lot of miniaturization including with the silicon photonics Mux/ Demux there.

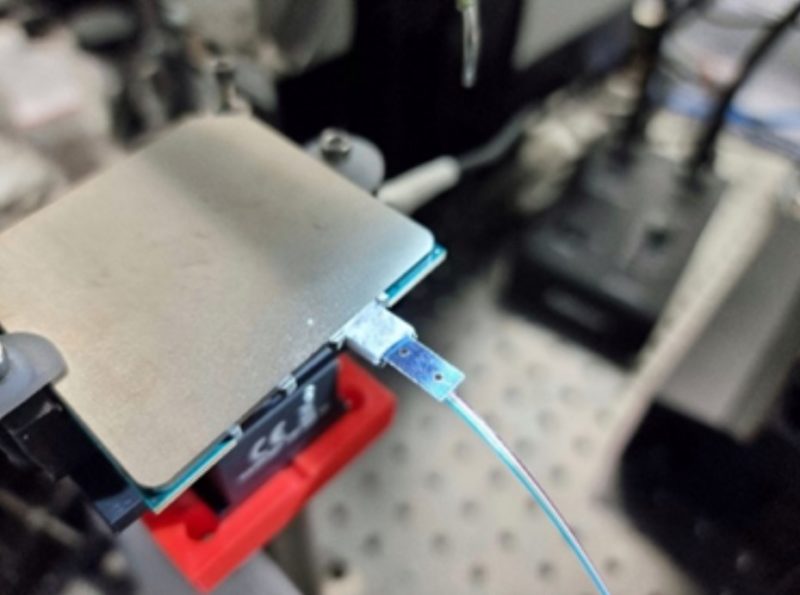

One component that the pluggable modules need, but Cisco does not have is the light source. Cisco’s vision is to use an ELSFP (External Laser Small Form Factor Pluggable) module as a light source. Cisco says that the laser light sources are the least reliable parts of the optical modules. Thus, moving them away from the switch ASIC and to a field serviceable pluggable module helps solve the serviceability issue. We have seen others like Intel create a connector partly for this reason.

Field serviceability remains one of the biggest challenges to co-packaged optics since removing a switch if one of 64 or 128 links fails is not ideal. Cisco thinks that using remote pluggable light sources it can get close to traditional pluggable optics reliability.

Final Words

Co-packaged optics are very cool for switch chips. At the same time, these are the leading edge devices for something we are expecting in the next 3-5 years becoming more commonplace. Chip-to-chip such as CPU-to-accelerator or even to CXL memory in systems is going to need longer reach and lower power options in the future. While Cisco and the networking world are trying to figure out how pluggable modules (with low-cost DACs) can be pushed, this is a broad topic for the industry that will need to be addressed. Co-packaged optics are no longer science fiction shown by a company every few years. There are teams of very bright engineers working on this across the industry today.

This proposed std is so dead, considering it requires the new cabling(since its not compatible with ALL the kinds of fiber termination or with existing SFP).

So instead of swapping a dead SFP going forward we need to swap the entire switch…

They’re saying that the reason the SFP dies in the first place is because of the laser. So, the lasers are used in a pluggable form factor.

Many years ago Nortel used to do co-packaged MTRJ style optics. It works well until ports die. With SFP everything was modular, so if an optic goes bad just swap it out. With co-packaged, a dead port is a dead port and on a 400G switch, would you rather do rip/replace for a bad port or just swap an optic? Wouldn’t a simpler solution be to go back to the SFP design and see what can be done to reduce power consumption? I’ve seen side by side optics of the same spec (different suppliers) vary by a few watts each, every supplier sources components globally…40nm vs 28nm vs 22nm vs 14nm has a lot power range. Even within the datacenter running SM optics is starting to become common with some businesses (think of only needing to stock one jumper style, one optic style). 10km are overkill, down-power the output without external attenuators to reduce power consumption. Be smart, don’t over-engineer a headache for customers.

There’s 2 parts of the sfp that can fail, the emitter (laser/diode), and the sensor. Cisco/Intel’s claim of failing lasers primarily might be true, and putting the laser on the SFP leaving the sensor on the co-package, would mitigate the death of a laser…but the sensor is on the co-packaged ASIC.

In my experience, sensor part of the package is made fragile by “hot” lasers being used, this happens usually when there’s a short run of fiber used in combo with a more powerful laser. Ex – 40km sfp on a 500m fiber will eventually burn out one of the SFP receiving parts, lasers show light both directions but error’d signal on one end.

I suspect they will have very tight language on the warranty of the ASIC and emitter powers used. If it were engineered however to attenuate power at the sfp…but that probably defeats the cost savings.

One great side benefit about integrated optics is what it can do for Cisco’s revenue when the optics come built into the switch and can’t be provided by a 3rd party:

* FS.com 100Gb SR optic: $100

* Cisco 100Gb SR optic: $1,889

On a 64-port switch:

* FS total: $6,400

* Cisco total: $120,896

I would be pretty surprised if Cisco would not bake the prices of their optics into the new switch price for the Copackaged Optics switches.