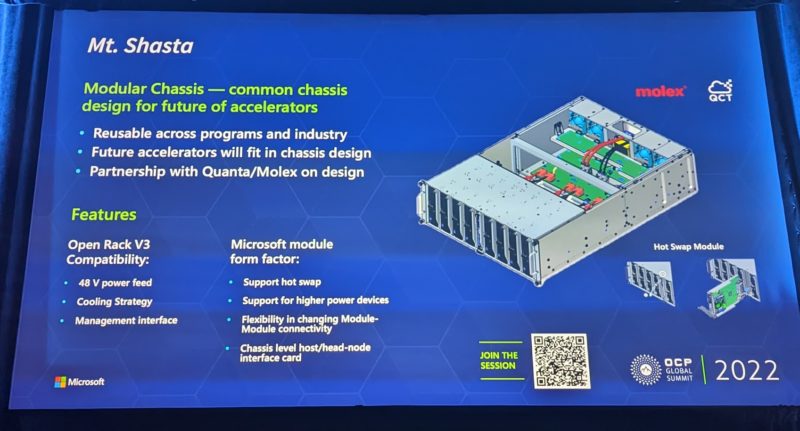

Microsoft is heavily invested in FPGAs and ASICs. At the same time, it faces a practical problem. Putting a FGPA or ASIC in a PCIe slot limits the power and cooling available for these devices while at the same time increasing heat generation in traditional servers. As such, Microsoft tapped QCT and Molex to build the new OCP Mt Shasta Platform to house its growing farm of accelerators.

Microsoft QCT Mt Shasta Platform for FPGA and ASIC Farms at OCP Summit 2022

The chassis itself was shown at the Microsoft OCP Summit 2022 keynote. Microsoft’s Open Rack V3 chassis takes 48V bus bar input power input and has shared cooling for up to eight accelerator blades. Using this setup, Microsoft is able to deliver power and cooling to high-power devices. It also features hot-swap capabilities and the ability to have flexible device connectivity.

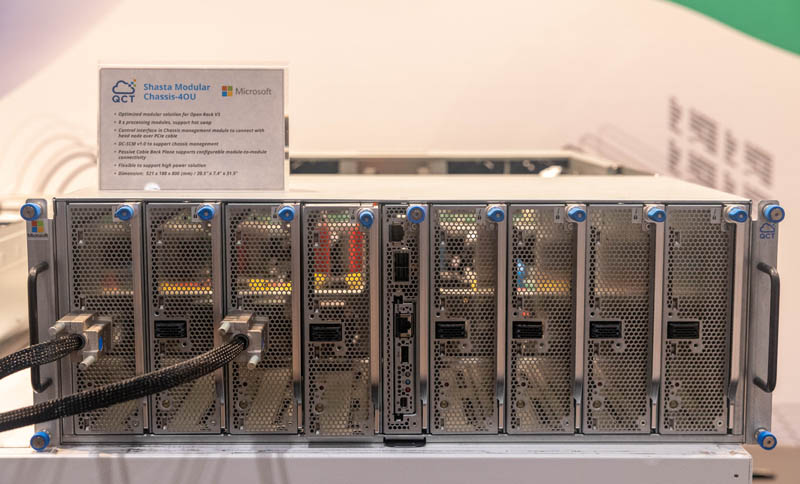

There were two of these chassis on the show floor that we took photos of. One was in the Microsoft booth. The other was in the QCT booth. Here is a look at the front of the system in the QCT booth. As a quick note, half of the materials at the show called this “Mt Shasta” the others simply “Shasta”.

Each of the ASIC/ FPGA modules locks into place and then there is a smaller middle module.

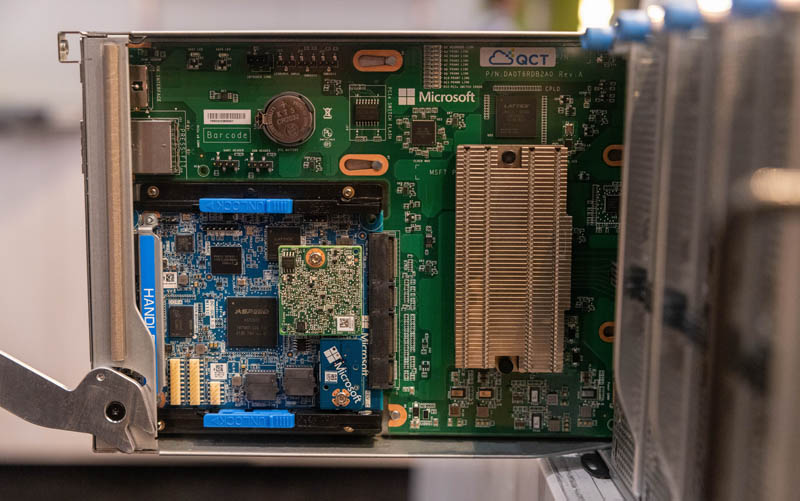

That middle module houses a DC-SCM for management. The SFF ports on the front of the module are to allow lower performance links to host systems for management.

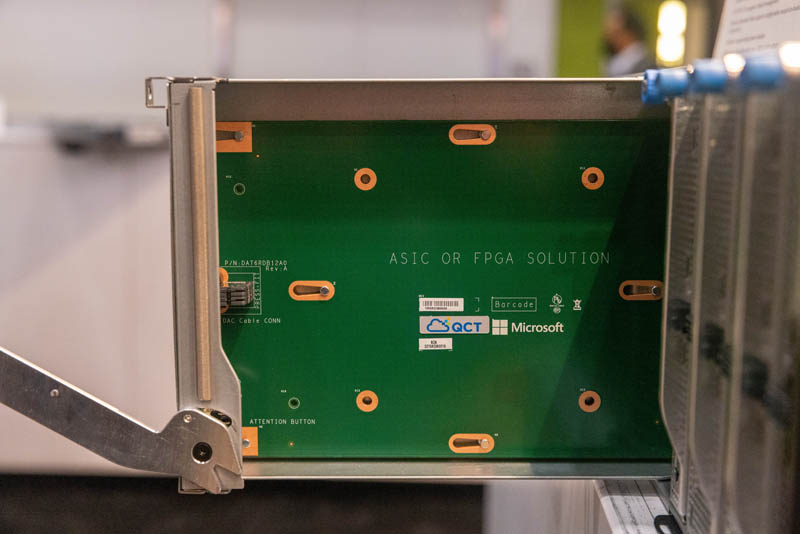

Here is a look at the ASIC/ FPGA carrier card with a fairly blank PCB.

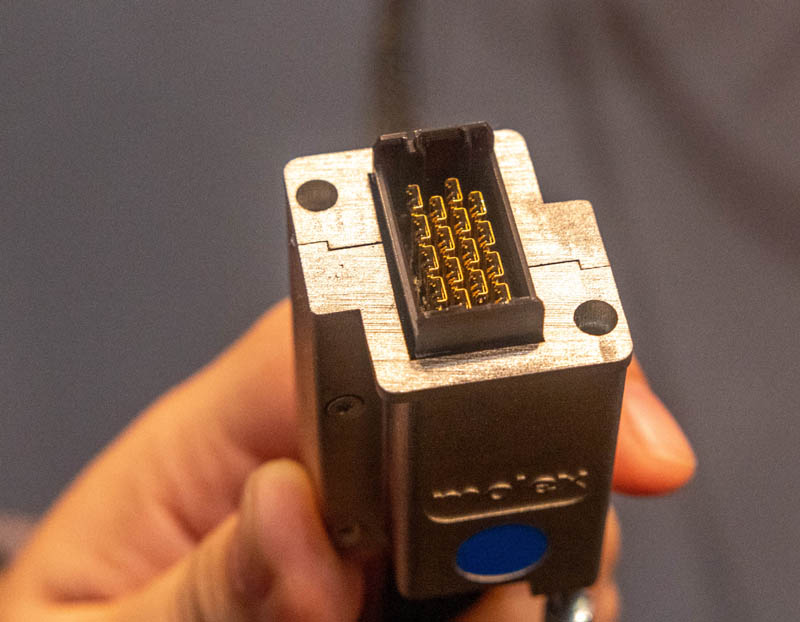

One of the features one will immediately notice is that there are external DACs made by Molex.

Here is a quick look at those connectors:

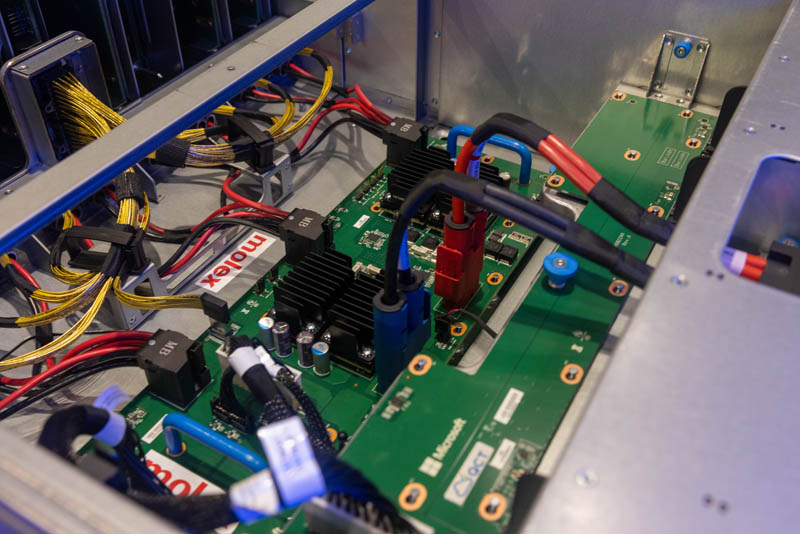

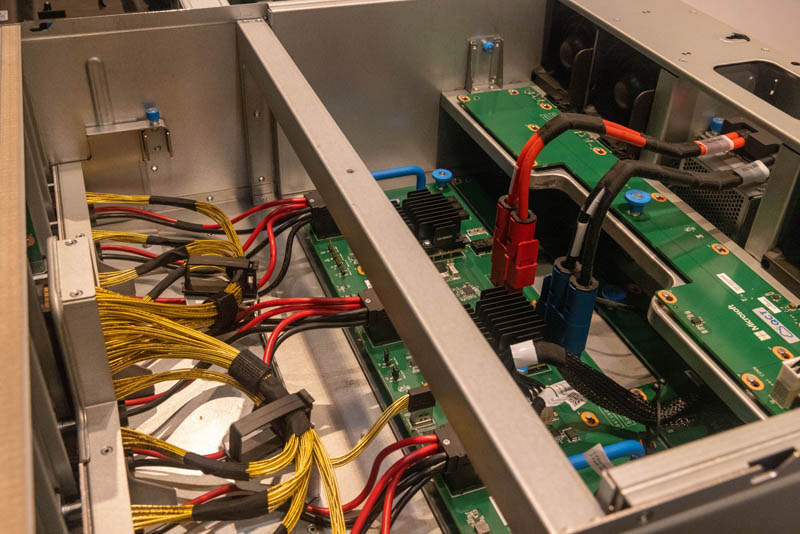

The back of these blades has the mating parts as well as cables between the management module and the individual FPGAs. Instead of a PCB backplane, Microsoft is using a cabled backplane here.

Power delivery is a huge feature of the box since this is designed for high-power accelerators.

Here is another view of the inside of the chassis.

At the rear we have a fan array and the bus bar power.

This is a quite interesting solution since Microsoft is targeting higher power/ cooling and serviceability.

Final Words

Overall, the Microsoft/ QCT Mt Shasta/ Shasta chassis is interesting. Microsoft told us that the reason it is not using OAM as a PCIe alternative or EDSFF E3 is that it needs higher power and hot swap capability. OAM offers power, but not hot-swap. E3 offers hot swap, but not high power. PCIe slots offer neither hot swap nor high power operation.

It would have been more interesting to see this fully populated, but hopefully this at least gives our readers some sense of the capabilities of the new system.

They more than likely went with cable due to the connector loss when going pcb-pcb and cost of using exotic pcb material

Seems very META product.. showing an accelerator array with no actual fpga or just blanks.. is just inventing another N+1 standard.

The narrow P2P connections could have been made by a secondary edge connector.. like the Apple has customized the PCIe to its own liking with the Mac Pro.

Its hard to tell what scale they target.. as larger you go.. less there is a need for blade/node hotplug necessity.