In our Inspur NE3412M5 review, we are going to see what this unique server offers. Unlike many rack servers, this server is designed to be portable and shipped to various edge locations whether those are in buildings or in vehicles. It was specifically designed to be transportable to various edge locations so hyper-scalers and other organizations can offer local and low latency CPU and GPU compute along with storage. If you want to see a truly portable server designed to be transported in the back of a truck and deployed quickly upon arrival, this is that system from Inspur. Those same properties make for an interesting review.

Inspur NE3412M5 Hardware Overview

As we have been doing in our recent reviews, we are going to split this into external and internal versions. There is a lot to see here so it makes sense to split this up.

Inspur NE3412M5 External Hardware Overview

The system itself looks like a tower chassis, except different in a key feature. It looks like a Pelican case and a tower server were mixed together. In a way, that is exactly what this NE3412M5 is.

The chassis itself has rubber feet on the bottom and the bottom side panel to help with shock and vibration when it is deployed. While most of Inspur’s servers we review are rack-mounted, this is a machine designed for edge deployment.

The system itself when it is completely closed does not have any ports exposed. What it does have are a few panels that expose functionality below. Perhaps the most exposed functionality aside from the rubber feet is the top handle which allows easy transportation of the system.

Around that handle is a panel that can be used to store the cabling. Since this unit came directly from deployment in China, it had an appropriate regional power cable but one can use this area for other power cable options as well as to store gear such as network cables.

On each end of the chassis, there are two doors that open. We called this the “port” side as traditional front and rear labels were probably less descriptive. Here we can see an out-of-band management port, a VGA port, two 1Gbase-T ports, two SFP+ 10GbE ports, and an array of six USB 3.0 ports. There are also a large number of LEDs and power/ reset buttons on this side.

One can see two fan vents for cooling and there is also what looks like another expansion slot that is not populated. We will show the other side of that when we get to the internal overview.

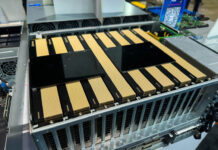

The opposite side has additional fans and the power input. The power supply in our test unit is a single non-redundant PSU which is more common on devices like this since in the field there is often a single power source. Perhaps the big feature though is that one can see a double-width PCIe expansion slot with a GPU installed. This system is designed to provide AI inferencing to the edge and this is a great example of how that is accomplished. In our internal overview, we are going to get more into how this is deployed since it is a novel solution.

One item that is really nice here is that covering both port sides of the chassis the doors can be retracted into the chassis. This allows the system to be protected during transport but then have the ports exposed when it arrives at its destination.

What you may have noticed from the first few images is that the side panels are big, and have an extensive system to secure them to the chassis. There is a bit more than just that going on. This solution is designed to securely hold the doors in place while distributing the pressure on the chassis to maintain proper seals.

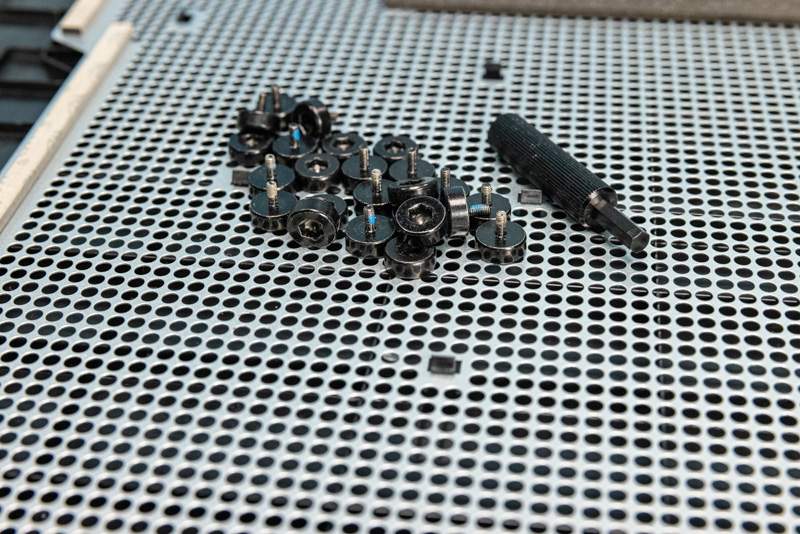

Inspur provides a tool to open the sides of the chassis, but one will likely want to use a drill bit instead to remove them. There are a total of twelve screws on each side, and each side may need to be accessed in the system depending on the components required. Using the hand tool, this took a while to unscrew 24 screws. One item we wish is that Inspur adds in a future generation is the ability to secure this tool in the compartment that houses the power cable around the handle. It would be great to see a dedicated spot there for the tool.

Now, that we have discussed the panels, let us get inside the system.

You didn’t mention weight, but it looks heavy.

Man this is cool. I wish you’d have done a video to see those doors open in action

Interesting approach to a specific market segment.

The interior views were “off putting” to me. Can you say “cramped”? I knew you could.

Long-run data covering interior case thermals would be interesting to see. All the durability in the world means nothing if the hardware slowly roasts itself.

Note to all HW manufacturers: Leave the roasting and smoking to a qualified chef in a proper kitchen.

Also curious to not see a label that says, “No user serviceable parts inside”, but then again the case labels are not in English, perhaps for good reasons.

This is a small form and looks more “efficient” than “cramped”.

to sleepy and awake – either here or in the vast majority of cases and server internals the recent lenovo DIMM fan shrouds notable for rarity — now we’re entering a fast paced generational upgrade sequence, I’m starting to think it’s lazy and can’t understand why the engineering isn’t of sufficient economic value to manufacturers when I think my company would tolerate a 5 percent price hike just to get given useful numbers about thermal characteristics

there’s no obvious thermal circulation design here or anywhere and I think that’s just poor in this age

to awake

this is why modular encapsulated subsystems on the CXL busses of the near future are where I hope we’re going. VME bus… hmm!

I really hope you do a video on this, I am really enjoying your movies on Youtube.