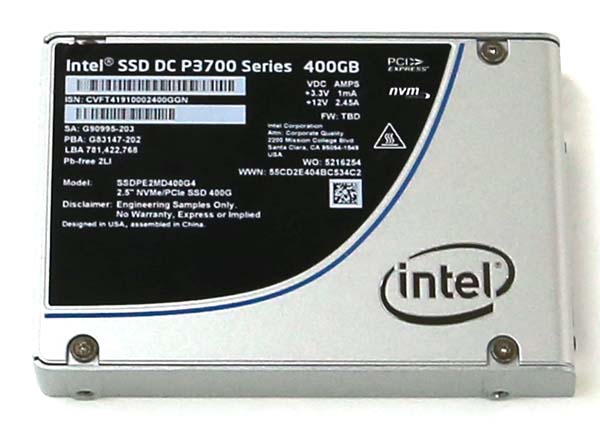

Today we are going to take a look at the internals of a 2.5″ SFF Intel DC P3700 400GB drive. The company made a splash when it released the Intel DC P3700 series of NVMe SSDs. The most common form factor at its release was a PCIe slot based drive. The cards were able to use up to the maximum 25w, which is reasonably simple to cool in a majority of chassis. The slot based approach was straightforward as it was based on a standard dating back at least three generations of processors, instantly providing an upgrade path to millions of late-model servers.

On the other side of the equation was the 2.5″ SFF drive form factor model. This was the decidedly different approach to the market. There are simply not a lot of 2.5″ NVMe capable chassis in the market. As this is being written, we no longer have a platform that can support this drive but have racks of platforms that will support the slot-based P3700. The key is that the 2.5″ form factor NVMe drives utilize a cabling system much akin to newer SAS drives to provide PCIe lanes to a backplane. For anyone using SAS drives, this should be extremely familiar.

There are four screws on our engineering sample that open the top cover. Inside we see a top PCB covered by Intel branded NAND packages and thermal transfer material. One can also see an absolutely massive capacitor onboard. Much like Intel’s current generation S3700 and S3500 designs, the PCB has a cutout for the capacitor. Unlike the S3700 and S3500 drives, the capacitor on the DC P3700 is massive.

Near the bottom of the PCB in the picture above we see two small black clips. By pushing these back we can see a bit more about the middle of the sandwich: it is fairly empty. The black spacer outlining both PCB parts is clearly seen and the large capacitor provides a solid reference point for the size of the rest of the assembly. Inside there appears to be Micron branded RAM packages but little else.

The two pieces of PCB are connected via a flexible (but stiff) connection. This was stiff enough that it held up the PCB for the shot below. One can see this connective pathway in the shot above (large copper looking band at the top of the drive.)

The question naturally arises as to what is on the bottom side of that other PCB. After about 15 minutes of trying to gently remove the PCB, it seemed as though we were rapidly hitting a point of no return. Since there was further testing to do, we opted to come back to this later and try again. What we do know is that the main shell of the drive still in the picture above has small heat sink fins so that side is expected to generate much more heat.

Why go through the effort for a 2.5″ form factor?

Surely, a newly cabled form factor may not seem necessary. One is essentially taking PCIe lanes and putting them over a cable when the majority of systems have slot-based PCIe lanes. Here is the big reason: Supermicro-Intel have a working version of NVMe hot-swap that was first demonstrated at IDF14 in September. We had a brief time with such a system and it does indeed work. Other vendors were following suit and are nearing validation of solutions. Hot-swap makes PCIe based SSDs highly serviceable. No longer does a server need to be pulled out of the rack and opened to replace a failed card or update to larger capacities. Instead, one can simply use a hot swap bay. In terms of field serviceability, that is a major benefit.

The rumors we have heard are telling us that these are extremely popular and the demand on components is quite large. Our take is that Intel will be pushing this as the SAS replacement for the next few upgrade cycles.

So they’ve folded a normal card into two and put it into a 2.5″ casing.

I’d been clueless how this worked until I saw your pictures. Thankx

Ask your intel guys when we are finally going to see the P3500 cards in the channel, its been too long. The 3700/3600 are awesome beasts but quite pricey (and gouged from a lot of vendors) where the 3500 for a workstation that won’t be writing 24/7 is far more affordable.

Has there been any further attempt at disassembly? I’m planning on putting beefier cooling on the controller, which is on the side with the fins.