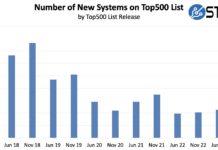

Recently we have had some time to use a very high-end solution in the lab. Agigatech, which is a Cypress Semiconductor subsidiary out of San Diego, California sent their AGIGARAM and PowerGEM products for testing. Since this is a fairly complex technology, it was an effort for Agigatech, Micron and Supermicro to get STH the necessary supplies to test the NVRAM solution. For those wondering, the basic function of this technology is to provide a RAM solution that can survive power failures. From a high-level conceptual reference point, it is somewhat similar to what we see in RAID controllers with Flash Backed Write Cache (FBWC) and even inside SSDs with super-capacitors. The main difference here is that a NVRAM solution for main memory allows one to restart a machine in its last state. This is just a quick look at the physical components. There is a lot more going on with the system to get this work which we will get into in a future piece.

The Agigatech AGIGARAM and PowerGEM hardware

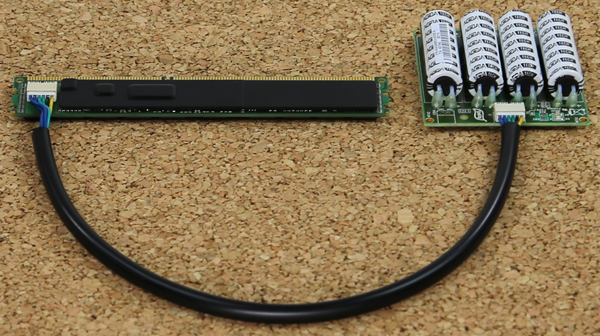

There are three main components to the AGIGARAM plus PowerGEM solution: NVRAM module, capacitor and cable.

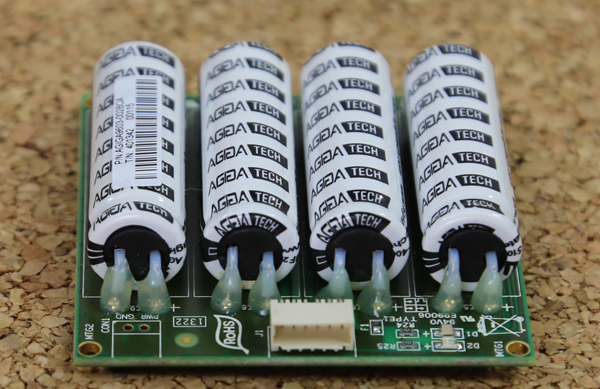

The PowerGEM comes in several form factors. We got the standard model which one mounts similar to how a BBU or supercapacitor is mounted via cable on a RAID card. In terms of scale, the capacitors are about the size of AA batteries. Four are mounted on a PCB and one PowerGEM is used for each DIMM.

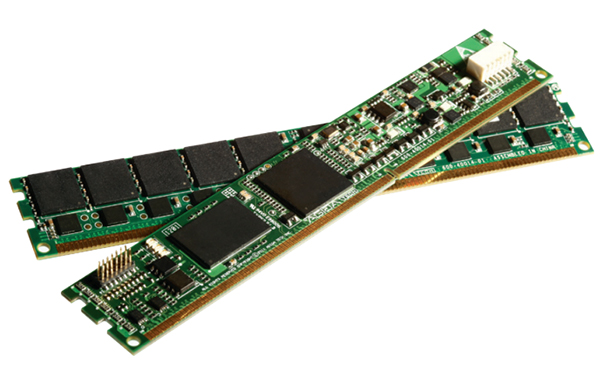

The second component is the memory. The NVRAM DIMMs appear to the operating system as 4GB DDR3 1600MHz parts (PC3-12800). The memory is sourced from Micron and the unit carry Micron labeling.

Agigatech provided this image of the AGIGARAM units with the heatsink removed. You can see the DRAM side (behind) and the NAND side (top). In the event of a power failure, the SDRAM transfers data to this NAND memory.

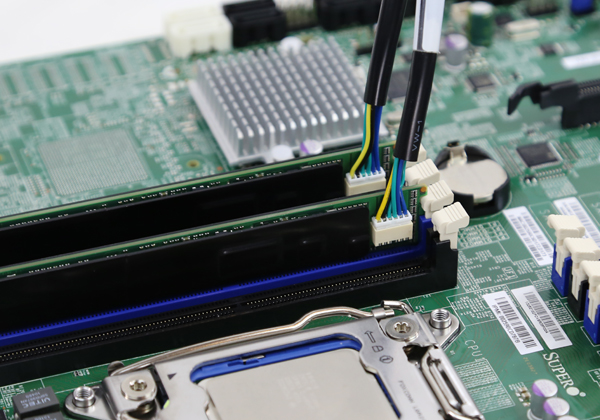

On the modules one can see a white 6-pin connector which is similar to what we saw on the PowerGEM. These are connected using a 6-pin cable.

Here is a view of the circuit that is created when the AGIGARAM NVRAM module is connected to the PowerGEM super-capacitor.

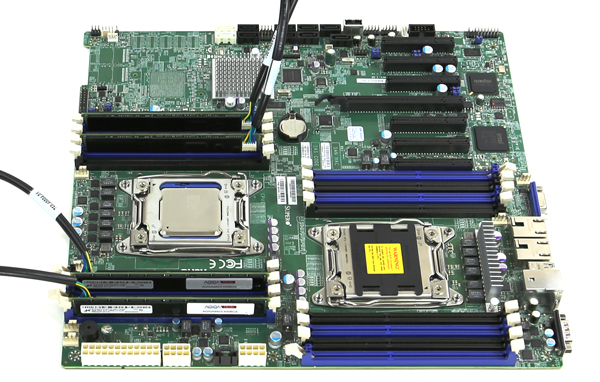

As mentioned earlier, these modules do require special motherboard support. We managed to get a Supermicro X9DRH-iF-NV to use as a test platform. Since we are using 4 modules, we are testing in a single-CPU configuration.

As one can see, these are fairly low profile DDR3 modules that fit in standard DDR3 DIMM slots. The cables are then connected to the modules once they are seated.

Here is a view of what this looks like from the other side once everything is plugged in.

Bottom line, this is certainly going to be an interesting solution. We will get into the benefits of using capacitors versus batteries for this type of arrangement, show testing results and explain more in depth what is going on with the system in the next piece. Stay tuned for more updates.